Slave to the Game

Online Gaming Community

ALL WORLD WARS

REPORT ON ROCKET POWER PLANTS BASED ON T-SUBSTANCE

by Hellmuth Walter

* Hydrogen Peroxide

In the search for an energy source independent of air for the propulsion of underwater craft, attention was early concentrated on T-substance. It was possible to convince the OEM [Navy High Command] very quickly of the importance of this material. In 1934, the first experiments were undertaken.

A difficulty was at once presented "by the limited concentration that had "been attained. At first only 60 percent T-substance could be supplied; this amount was later increased to as much as 85 percent. Decomposition and combustion experiments conducted on the grounds of the CPVA in Kiel-Dietrichsdorf led to the first practical information as to the technical feasibility of the use of T-substance. New perspectives soon developed because a method of concentrated energy production had been found here, which was capable of many applications. The idea of using this energy for the propulsion of missiles either in guns or as rockets suggested itself and appropriate proposals, which quickly led to the construction of the first experimental devices, were made to the official quarters concerned.

In January 1937, the first flight of a DVL aircraft with T-substance auxiliary propulsion took place at Alimbemuhle in the presence of Colonel Udet, who piloted the third flight. In June 1937, the first T-substance rockets were fired (Altenwalde). Then in rapid succession take-off auxiliary, main propulsion, and other rocket drives were brought out in experimental versions.

T-substance. - Hydrogen peroxide is a well "known chemical, which is widely used in the textile industry. Its chemical and physical properties as well as the processes of manufacture and use are familiar and have been described in voluminous books and papers. Nevertheless, much developmental work was required to open the way for T-substance as a usable oxygen carrier. In fact the utilization of hydrogen peroxide as the oxygen carrier for energy production had hitherto been the subject only of isolated suggestions, which have never been developed beyond the stage of theoretical discussion. Because only low concentrations had been necessary for the previous uses of hydrogen peroxide and, conversely, the manufacturing cost of higher concentrations was considerable, there had been no stimulus whatever to the manufacture of higher concentrations and the higher concentrations were indeed not commercially obtainable. The question was raised of increasing the concentration in order to reduce transportation costs. The customary 30-percent commercial product certainly offered no incentive for use a3 a source of energy. Conversely, higher concentrations had acquired the unfavorable reputation of being dangerous with respect to storage, probability of explosion, and so forth. This reputation found expression, for example, even in the freight rules of the state railways. This prejudice, nourished by some accidents due to lack of knowledge and experience with higher concentrations, had an extraordinarily retarding effect on the technical utilization of hydrogen peroxide as an energy carrier and to some extent still must be contended with today.

After the manufacture of a sufficiently pure and stable product of high concentration (first 70 percent and later 85 percent) had been attained by the EWM process, it was possible in 1936 to design and test the first devices for rocket propulsion. With the experience and knowledge gained in the subsequent years, it is claimed that — presupposing, of course, certain conditions as to handling and storage T-substance is today an entirely reliable propellant. (A more detailed exposition will follow subsequently.)

The substance itself will now be discussed in detail; in this connection some familiar facts may be repeated.

In view of its chemical components, hydrogen and oxygen, hydrogen peroxide or to use its briefer code name, T-substance, appears at first a positively ideal oxygen carrier. Unfortunately, even in 100-percent concentration only 47 percent by weight is available as oxygen for reactions with fuels. For an oxygen carrier this -is a relatively small proportion.

In the case of nitric acid, for example, 63.5 percent "by weight is available as oxygen not to mention the case of pure oxygen.

This disadvantage is, however, almost entirely offset "by the relatively high heat of decomposition released in the disintegration of T-substance into its components H2O and 02.

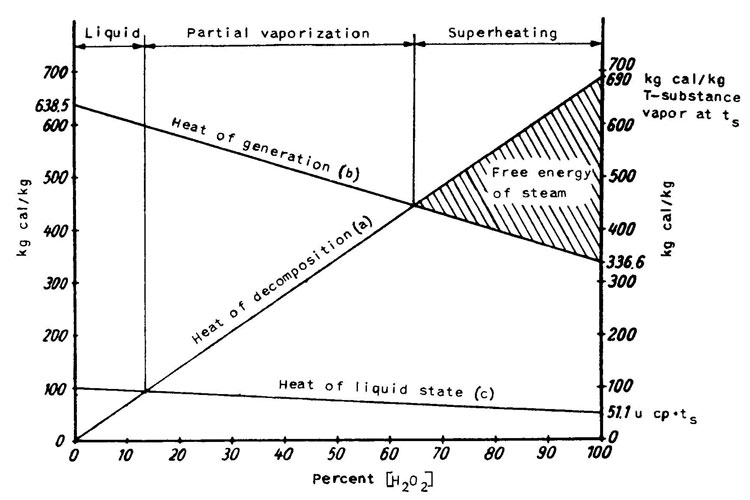

In the decomposition of a 100-percent solution, 690 kilogram calories per kilogram are released, enough to heat the products of decomposition to a final temperature of about 950° C. The relations between concentration, heat content, and decomposition temperature are shown in figure 1.

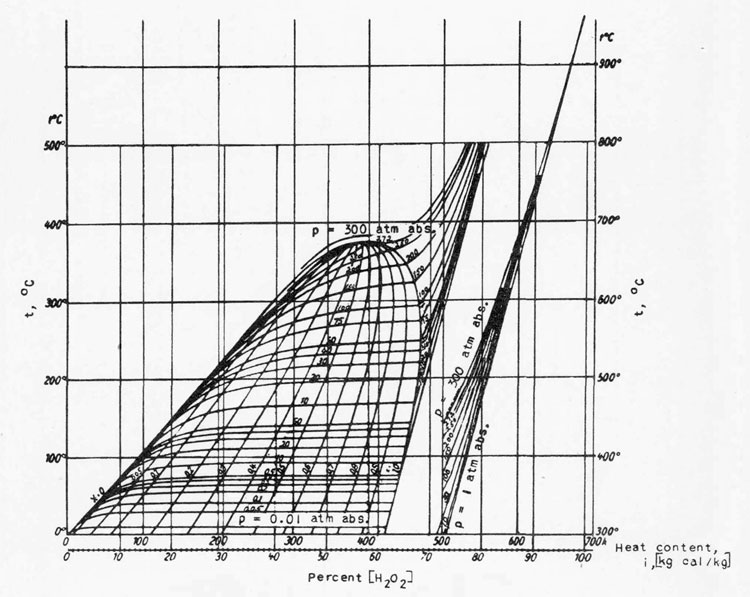

Plotted against the concentrations, 0 to 100 percent, -the heat of decomposition (a) increases in a straight line from 0 to 690 kilogram calories per kilogram. The heat of generation of dry saturated steam (b) (which at zero concentration is 639 kg cal/kg) decreases with increasing T-substance content because of the decreasing water content. Also the heat of the liquid state (c) decreases with the lesser specific heat of T-substance. At a concentration of 13.5 percent, the intersection of (a) and (c) indicates that the heat of decomposition is just sufficient to heat the water produced and the oxygen to the temperature of vaporization (100° C). At higher concentrations, partial vaporization is attained until at 64.5 percent (intersection of (a) and (b)) all the water is converted into steam. Beyond this point, the surplus heat of decomposition serves to superheat the gas-steam mixture. For example, at 80 percent a temperature of 465° C is found. The relation between concentration and final temperature of decomposition at other pressures is shown in the t-i diagram, figure 2. Along the line p = 1 atmosphere absolute, between 0 and 13.5 percent a rise in temperature to about 100° C occurs; between 13.5 and 64 percent a mixture of steam, liquid, and oxygen is produced and above 64.5 percent a superheated mixture of steam and oxygen. At different pressures the boundary points are shifted as indicated by the left and right boundary curve.

This behavior of T-substance during decomposition is fundamental to its importance. On the one hand, in spite of the smaller yield of oxygen the release of the heat of decomposition places T-substance in the same order of magnitude of total energy yield as other oxygen carriers; on the other hand, the utilization of the heat of decomposition offers inestimable advantages in the use of T-substance in power plants, particularly for auxiliary propulsion.

The close interdependence between concentration and steam temperature makes possible an Infallible system for the generation of steam of an absolutely constant temperature, -which cannot be excelled by any of the hitherto known steam-boiler techniques with respect to controllability, simplicity, and low weight cost as well as small size of the installation for a given output.

Preparation of Pure T-substance

The preparation or decomposition of T-substance occurs by means of catalysts. Apart from certain precious metals, for example, platinum sponge or platinized pumice stone, the most effective catalyst is permanganate, which may be used in the form of a water solution of sodium or calcium permanganate of high specific gravity (1.5) atomized or sprayed together with the T-substance into a decomposition chamber, or used in the form of pyrolusite mixed with cement and sand to make catalytic stones, which are used as filling in the decomposition chamber and against which the T-substance is sprayed through atomizing nozzles.

In the present state of development of the catalytic stone, under normal operating conditions, that is, approximately 25 atmospheres gage, 150 to 200 grams per second of T-substance can be decomposed by 1 kilogram of stones, or a total of about 2000 kilograms during the life of 1 kilogram of the stones. This high rate of flow puts such a considerable mechanical stress on the stone that a certain degree of erosion of its mass must be expected. Again, ordinary T-substance contains so much residual acid that the stones would soon be polluted. Therefore, distilled T-substance is used for surface decomposition.

In decomposition by the use of sodium permanganate, a reaction occurs involving the formation of sodium hydroxide and pyrolusite after which the true catalytic action occurs; however, only by atomization into the finest particles can the great effectiveness of the permanganate, which makes possible the decomposition of 1 kilogram of T-substance per second in 1 liter of decomposing volume, be exploited.

In the development of fuels and combustion chambers for the combustion of oxygen, the following are the outstanding requirements:

1. Highest energy production, that is, lowest specific consumption

2. Lowest possible combustion-chamber temperatures

3. Reliable ignition as far as possible without special auxiliary means

1. Without doubt, the first requirement is best fulfilled by the hydrocarbons, which at the same time satisfy the requirements of condensability and solubility for the exhaust gases of underwater power plants. However, neither ignition without special auxiliary means nor combustion in a small space without the addition of a catalyst is possible. As a catalytic agent, sodium or calcium permanganate - in smaller quantities - also may be used here. A power plant of this kind exists at present, namely the combustion- type take-off auxiliary. The system is very reliable but because of the three components it requires much apparatus and hence leads to undesirable complications in a controllable installation.

2. The second requirement is, in general, already fulfilled by the use of T-substance. The combustion of hydrocarbons with 80-percont T-substance produces temperatures of about 2200° C but the same consumptions using nitric acid produce about 2750° C.

3. The third requirement is fulfilled today by the use of hydrazine hydrate. However, because the heat value of hydrazine hydrate is only 2822 kilogram calories per kilogram, a mixture of hydrazine and methanol is used, the ignitability of which is still adequate. A further decrease in the proportion of hydrazine, which would lead to a higher yield of energy, is for the present not utilized for reasons of safety although experiments have shown that use of such a mixture is certainly possible.

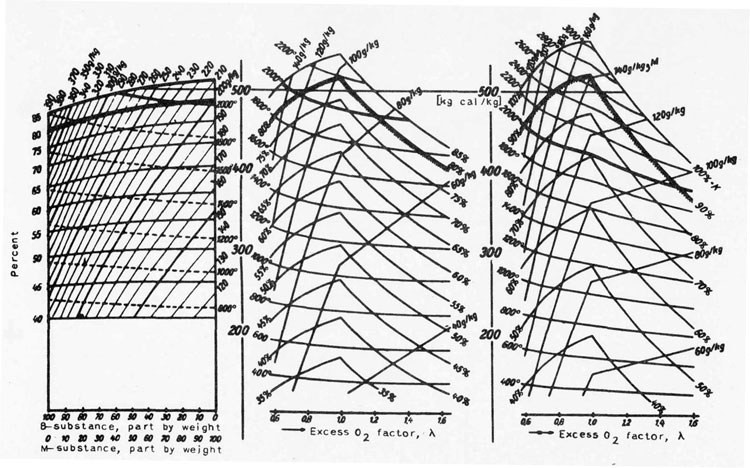

In figure 3, the adiabatic drops and the temperatures are plotted against the concentrations and mixture ratios for the T-substance, C-substance and T-substance, and Sv-sub3tance hydrocarbon systems. [NACA comment: C-substance is a mixture of hydrazine hydrate and methanol; Sv-substance is 90 percent of 98-percent nitric acid plus 10 percent of sulfuric acid,]

The diagrams show that about the same drops are attained in the combustion of hydrocarbons with 80-percent T-substance or with 90-percent Sv-substance but that with Sv-substance the temperature- is substantially higher.

With the use of hydrazine hydrate, about 4 percent of the drop must be sacrificed, in return for which a lower temperature burden on the combustion chamber and, above all, reliable ignition and clean burning are obtained.

Incidentally, a similar reduction of the drop appears in the diagram for nitric acid when a change is made from hydrocarbons with a heat value of about 11,000 kilogram calories per kilogram to Visole with about 9000 kilogram calories per kilogram. [Visole is a fuel composed of vinyl compounds.]

Other Properties of T-Substance

The following properties of T-substance must also be mentioned as bearing on its suitability as an oxygen carrier in rocket power plants:

1. The specific gravity is relatively high, being 1.345 for an 80-percent solution. Nevertheless, T-substance is excelled in thi3 respect by Sv-substance,

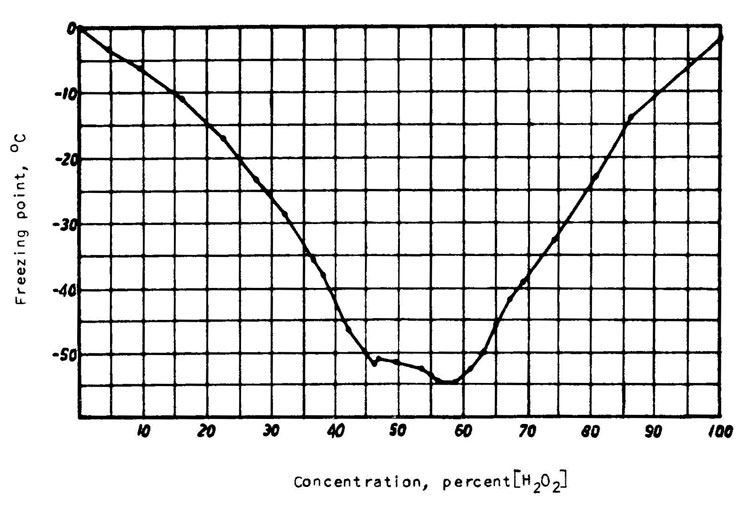

2. The ability of T-substance to withstand cold depends upon the concentration, At 52 percent, it reaches its lowest freezing point, about -50° C, while the freezing point for 80 percent Is about -25° C. [NACA comment: Lowest freezing point value inconsistent with fig. 4.] However, crystallization is generally very much delayed and requires the stimulus of crystallization nuclei; therefore, as a rule, significantly lower temperatures are possible.

3. The question of storage constitutes from the first a problem of the most stubborn nature. Only after its solution may T-substance be considered a suitable propellant.

The problem becomes serious in the case of T-substance when an interaction between the container and T-substance occurs resulting not only in a corrosion of the container and in most cases a consequent decomposition of the T-substance but also in heating in some circumstances to the critical decomposition temperature of about 140° C, which leads finally to explosion. This decomposition, incidentally, was probably the principal cause of the explosions that used to be feared so much.

For satisfactory storage, the addition of phosphorus and hydroxyquinoline or other substances to stabilize the T-substance is necessary. Impurities that may be present may make these additives ineffective and therefore the danger of spontaneous decomposition is increased. The question of insuring stability in storage must therefore also be approached by way of the container.

Suitable container materials include: alloy steels containing nickel and chromium, such as V4A, V2A, Remanit, and so forth, as well as-copper-free aluminum alloys, especially 99.5 percent pure aluminum, Eydronalium, brine-resistant alloys and the like, which have been anodized and coated with Oxin. The synthetics, Mipolam and Igelit, (polyvinylchloride) are also suitable as coatings. This type container with quite large dimensions has already been in use for a number of years without any trouble. With regard to storage in smaller units, extensive experiments were conducted for the OKM on torpedo tanks with such success that it was found possible to extend the period of storage even under tropical conditions (temperature of 50° C both continuously and intermittently) to as much as 6 months without trouble and without any considerable loss of concentration. Some of the experiments extended over even longer periods of time.

As the torpedo is an item subject to storage, the storage period just mentioned may be regarded as adequate for most other cases. For long term storage of nonrefillable expendable items that cannot be tested before firing, especially smaller devices under 25 liters, it would not appear that the use of T-substance should be recommended.

4. In this connection, the question of hazard to the containers from fire and bombardment immediately arises. This question has also been systematically investigated. Measurements were made of the rise in temperature in both open and sealed containers exposed to an external flame. At temperatures of about 90° to 100° C, a limited additional decomposition occurred first; the heat released by this decomposition hastened the temperature rise until at 135° C or 140° C a vaporization, which could no longer be restrained, occurred that led, however, not to a detonation but to a simple boiler explosion due to an excess of internal pressure. With a gas-escape valve of adequate size, the container simply relieved its pressure. At temperatures up to about 120° 0, it was possible to halt the vaporizing action by external cooling and to reestablish normal storage. In the presence of impurities, such as rust, copper gage tubing, or materials of similar catalytic effect, the process may, of course, be accelerated and under certain circumstances even detonation may occur.

Accordingly, a fire near containers not designed for high pressures would lead to the bursting open of the containers at the weakest seams or at specially provided points. Quantities of T-substance flowing into a fire will, of course, cause the fire to blaze up but without danger of explosion.

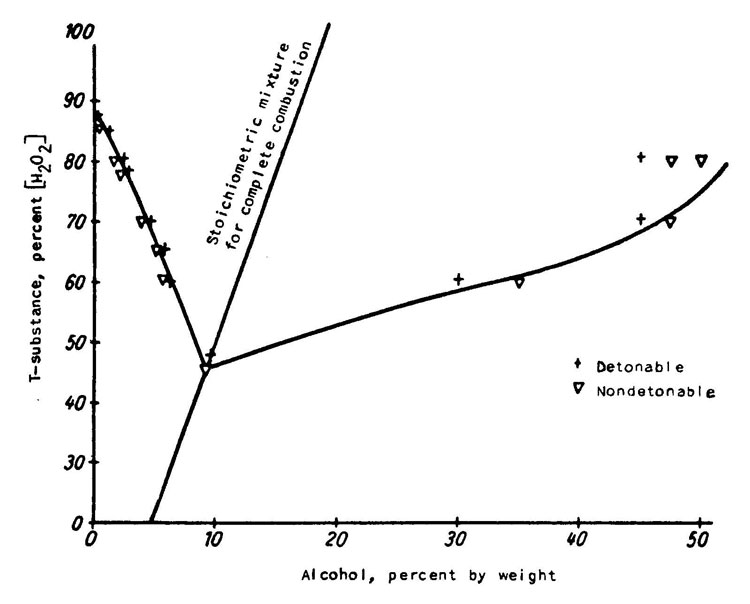

5. Safety under bombardment has also been extensively investigated, The Research Division of the Army Ordnance Office has carried out detonation tests with T-substance-alcohol mixtures of all concentrations, the results of which are shown in figure 5.

With the strongest excitation by extraneous shock, pure T- substance can be detonated only in concentrations greater than 87 percent. The stronger the mixture of alcohol, the lower the T-substance concentration at which detonation is possible until at the stoichiometric ratio the lowest point is reached at about 45-percent concentration of T-substance. From this it follows that the bombardment of T-substance tanks with explosive projectiles must have an effect similar to that of the bombardment of a water tank. Actually, there are only limited additional effects. Naturally, complications and dangerous situations can arise in the bombardment of combinations of different tanks containing T-substance, fuels, and auxiliary materials, especially if mixtures of considerable quantities of T-substance and fuels occur that do not at once ignite, that is, in the case of fuels that are not self-igniting because in such a case, as indicated previously, detonable mixtures will be formed, which constitute a greater danger to the scene of a bombing catastrophe than would the mere fire to which the flowing together of T-substance and self-igniting fuels would give rise.

Special mention should be made of the behavior of T-substance under bombardment with incendiary ammunition particularly rubber fire bombs, which after a certain delay in ignition could probably set off explosions; a fact that is especially to be taken into account in the design of larger storage installations for T-substance.

6. The question of transportation of T-substance may be regarded as having been solved by the systematic work done in this field. Since the provision of suitable cars with tanks made of aluminum according to specifications, permission has been given to transport T-substance by rail. Previously when T-substance was being transported by truck, various traffic accidents occurred that made it apparent T-substance was relatively harmless in such situations. If other inflammable materials are present and come in direct contact with T-substance and if means of ignition are also present, a heightened danger of fire naturally exists.

7. In addition to the question of transportation, of special interest is the easy handling of the material by the personnel at test rigs, flying fields, and so forth because the boiling point is about 120° C, the material may be handled almost the same as water in clean aluminum cans. The filling of the machines is accomplished through open funnels using cans or either hand or electric pumps. Supply lines of flexible Mipolam hose may also be used.

The personnel are endangered only by direct contact. The material has a mild burning effect on the human skin, causing whitish swellings of the tissue, which, however, disappear again in 1 or 2 hours according to the severity of the burn. The reaction is so slow that if the affected spot is immediately washed with copious quantities of water scarcely any traces of burning will be observed. Only an eye burn can be dangerous. Splashes on work clothing are undesirable because of the danger of fire and the damage to the fabric. The service crews are therefore directed to wear rubber or Mipolam aprons, foot coverings, and protective glasses, which, however, are only too readily forgotten when the work has become somewhat familiar. The provision of plentiful supplies of water close to the work and cleanliness in the assembly of all equipment are almost the only special safety measures required. As the escaping gase3 (composed of steam, oxygen, and carbonic acid) are also harmless, they do not give rise to any particular handling difficulties either.

8, Finally, a matter of very great indirect importance is the propellant-supply situation. Because, for use in rocket power- plants the requirements previously described that relate to long periods of storage must be fulfilled and also a high purity of the material is necessary for operating reasons, only the manufacturing process (by electrolysis) of the EWM in Munich has hitherto been satisfactory. This process requires a considerable expenditure of precious metals and electric current, and therefore the expansion of production is limited in the first instance by these factors. On the other hand, the progress of development of the T-substance power plant has increased the possibilities of its use. Therefore, work is being done on new processes intended to make it possible to meet the increasing demand on some other basis.

T-substance having thus been characterized as a highly appropriate propellant for rocket power plants with respect to output, operating behavior, storage, safety, and supply, the description of the power plant itself will now be presented.

The construction of rocket power plants is very largely dependent upon the uses for which they are intended; these uses may be classified as follows:

1. Short-period power plants in expendable devices, which include projectile propulsion, gliding bombs, remote control gliders, aerial torpedoes, underwater torpedoes, and so forth.

2. Short-period power plants that may be reused, which include take-off and landing auxiliaries, catapults, gas-pressure cannons, and so forth.

3. Controllable continuous-operating power plants, which includes rocket fighters and other aircraft propulsion, boat propulsion for engineer-corps use, and so forth.

4. Indirect drives and mixed power plants, for example, in jet suction and compression installations, which might be used for influencing boundary layers, E-L power plants [NACA comment: E-L designates a power plant combining the use of rocket propellants with the intermittent combustion and resonance or tidal-air principles of the intermittent ram jet. Used alone, L normally designates the Lorin tube, that is, continuous ram jet.], Melot nozzles, and so forth,

5. In addition to these use3 for rocket power plants, the generation of high-pressure steam from T-substance has possibilities of application to the most diverse uses, such as heating, production of compressed gas, oxygen generation, power boosting by the injection of T-substance in engines, and so forth, which, however, lie outside the scope of this paper.

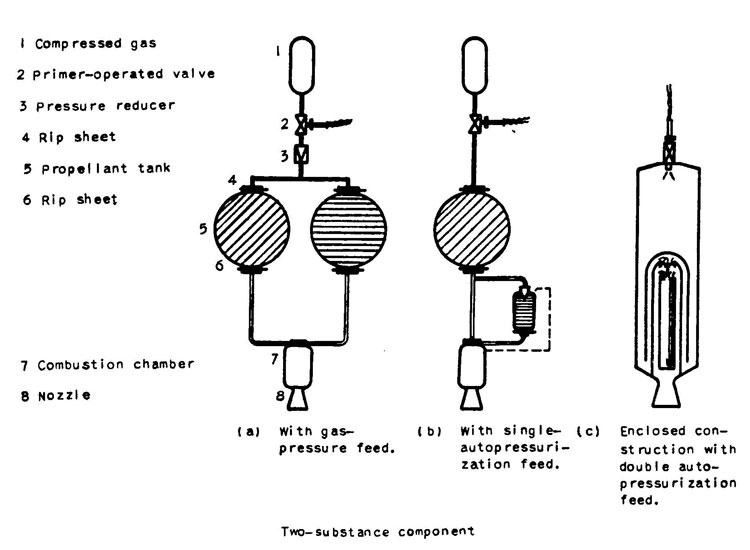

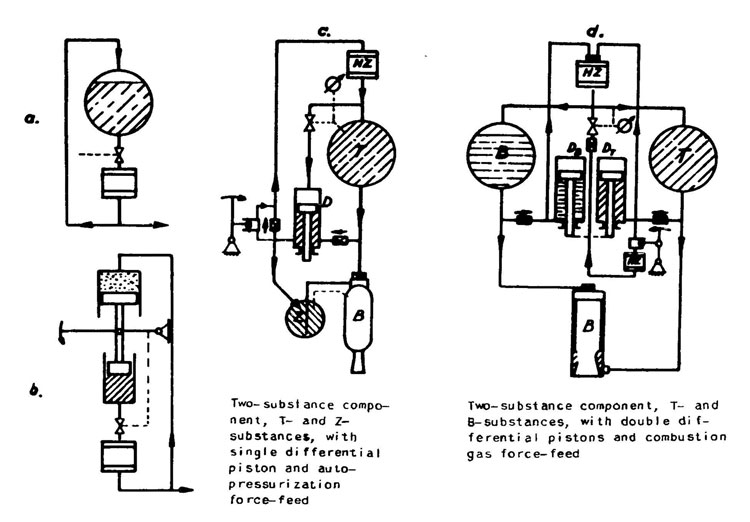

1. The schematic layout of a short-period power plant is shown in figure 6.

The principal characteristics of these units are very simple design, avoidance of complicated flow-control devices, very compact construction, and ability to undergo long storage. For the conveyance of the fluid propellants, compressed gas or air is particularly suitable.

The air flask is closed by the diaphragm of a primer-operated rip valve the reliability of which as a closure has been tested over a period of years. After this valve is opened, the air flows through a pressure reducer, which with short operating periods may often be replaced by a simple throttle, and either through sealing membranes designed to give way at a certain pressure or through check valves into the propellant tanks forces the propellant through the lower sealing membrane or non-return valve into the atomizer or mixing head of the combustion chamber in which the components react with each other. The combustion chamber ends in a Laval nozzle.

A good means of saving weight is the use of autopressurized pumping, which is shown in figure 6("b). At the present time, however, this method is capable of being reliably controlled only for the pumping of Z-substance [NACA comment: Z-substance is a catalyst of either sodium or calcium permanganate. ] by means of T-substance. A small quantity of T-substance is diverted from the pressure line, passed through a check valve, and sprayed into the Z-substance tank in which steam is formed until the pressure of the T-substance is reached; this pressure conveys the .Z-substance forward. The pressure is developed so rapidly that no delay in the pumping occurs.

Autopressurized pumping may also be used for conveyance of the entire bulk of T-substance, aa shown in 6(c). In order to force- feed 1 kilogram of T-substance at 20 atmospheres gage, about 10 grams of the material must be converted to steam, which in turn may be accomplished by the injection of about 0„2 to 0.5 gram of Z-substance. This form of autopressurization together with an enclosed form of construction results in a very compact unit. Unfortunately, the pressure cannot be maintained with an accuracy greater than about ±20 percent. This system is at present suitable only for units using T-substance and Z-substance as the pumping of fuels with an oxygen- steam mixture at 450° C is inadvisable because of the danger of self- ignition unless it becomes possible to store the fuel in and pressure- feed it from elastic and, at the same time, heat-proof bags.

The T-substance, Z-substance system has proved suitable in many cases for power plants of the simplest construction in spite of the relatively high specific consumption of 9.3 grams per kilogram second. The use of the system is prohibited, of course, as already mentioned for units of simple type subject to storage for more than 6 months, especially in the case of email units. In this respect the system is inferior to powder and other oxygen carriers. However, this system has a large field of application in the launching of glider bombs; which can be checked for operability at the field before being launched, as well as for all sorts of experimental drives, model rocket3, flying models, and so forth. Power plants have been constructed in all sizes from 10 kilograms to 60 metric tons of thrust and it is today possible to promise the success of such devices upon first trial, which is generally not the case with devices using combustion.

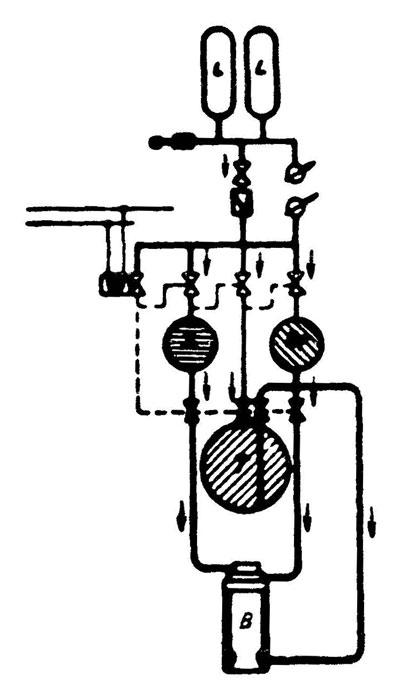

Figure 7 shows the .flow plan of a glider-bomb drive that corresponds in principle to the first layout shown in figure 6.

Air pressure feeds through ignition-operated valve, pressure reducer, and distributor to the two tanks for T- and Z-aubstance, and development of thrust occurs in the decomposing chamber equipped with nozzle. The total impulse of this unit operating by T-substance decomposition alone with a thrust of 600 kilograms for a generous 10 seconds amounts to 6400 kilogram seconds„ The empty weight of this unit is 68 kilograms, that is, 10.6 grams per kilogram second. Combination of this weight with the specific propellant consumption of 10 grams per kilogram second yields a total weight cost of 20.6 grams per kilogram second. [MCA comment: Values corrected from the German.] The ignition- operated valve, which is used the most, is constructed without any movable parts„ The high-pressure side is separated from the low- pressure side by a rip sheet. Touching the center of both sides of this rip sheet is a tube through which, upon the setting-off of the primer, the pressure wave created by the powder charge blows out the center of the sheet and the rest of the sheet folds up under the high pressure and lies against the walls. Thus a very reliable free passage without moving parts is created.

2. In short-period power units that may be reused, the construction fundamentals are naturally altogether different; whereas for expendable items subject to long storage the principal attention is devoted to the storage tank and the other parts are designed for use only once, in this case the demands upon the container material are secondary as compared to the design of the valve system, filling arrangements and other parts subject to wear, the interchangeability of single parts and of component groups, the control devices, and so forth. The flow plan (fig. 8) may in most cases be the same as for the case previously described.

Here again compressed-air force-feed offers advantages with regard to simple design and satisfactory operation of the unit. The air flask has a filling connection. The starting valve is electromagnetically operated and the rip sheets are replaced by check valves. The flow sequence and the start of combustion are controlled by a safety distributor valve, Units of this type include take-off auxiliaries and torpedoes (which must be reusable because of the necessity of aiming trials and test runs), as well as catapult power units and a recoilless cannon,

Because in units of this type a more extensive mechanical installation is permissible, it is appropriate to consider the replacement of the compressed-air force-feed, which requires an extensive and costly compressor station for charging the units, by the generation of high-pressure gas. The simplest case of high- pressure gas generation is shown in figure 9.

In figure 9(a), after the opening of the valve the T-substance runs by gravity into the surface decomposing chamber and is converted into steam. Because this steam is sufficiently pure, it may be led directly back to the tank and used as pressure-feed gas. In principle, the pressure can be raised to any desired degree, although a limit is set by the heating of the T-substance by the steam, which, of course, need not be dangerous if the entire working process is of short duration. On the other hand, the rate of pressure development is limited by the static supply head of the T-substance level and by the resistances in the inlet piping. The further development of these considerations as to the method of pumping leads at once to the separation of the T-substance chamber from that occupied by the steam and the employment of the differential piston system, as shown in figure 9(b).

After the opening of the valve, a small quantity of T-substance is sprayed into the decomposer by hand, by a spring device, or by other auxiliary means, to start the process; whereupon, the forced feeding of the T-substance proceeds at a more or less rapid rate according to the ratio of the piston diameters. The operation of the apparatus is similar to a duplex steam pump and by the addition of suitable pump and steam valves it can be made to operate continuously. Using this arrangement as the power unit for an automatic steam-pressure cannon, without difficulty 30 steam-generating periods per minute are obtained, a figure that could doubtless be further increased.

With larger quantities of T-substance, the pumping piston must, of course, be of considerable size, which will lead to awkward construction and above all to storage difficulties because of the necessity of a leakproof piston; therefore, an auxiliary steam- generating system based on this principle, as shown in figure 9(c), will be considered. Here the T-substance conveyed by the differential pump is not used as propulsion steam but only as a means of force- feeding the main bulk of the T-substance, which may then be decomposed either by a surface decomposer or by means of Z-substance force-fed by autopressurization.

Here again starting may be accomplished by auxiliary injection by hand, spx-ing, gunpowder gas, or the like but the filling of the auxiliary cylinder need not be done until the unit is being readied for use, if so desired. The application of this principle to gas generation for catapults has been accomplished and its use in this connection with a two-component system involving combustion is being developed. For this system, the flow plan must be extended as shown in figure 9(d), Because processes lasting a very short time, about 0.5 second, are involved in catapult operation, forced-feed may "be accomplished without danger "by hot. gases. In this case there is developed, as may "be seen, a double-piston arrangement for pumping the two components to the auxiliary decomposer; again the pumping action is started either by steam, from pure T-substance, by gunpowder gas, or by hand,, In the sketch, a rocket combustion chamber is shown as the point of utilization; this may, of course, be replaced by the combustion chamber of a catapult.

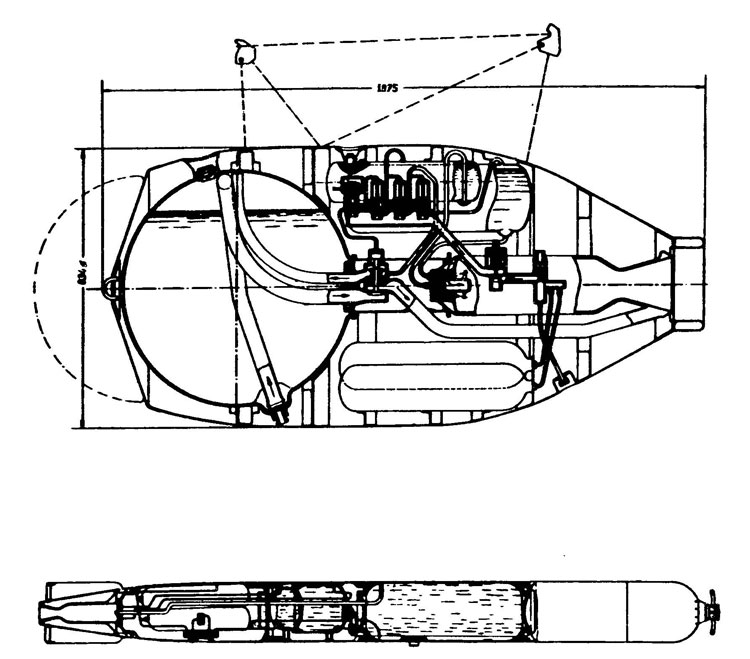

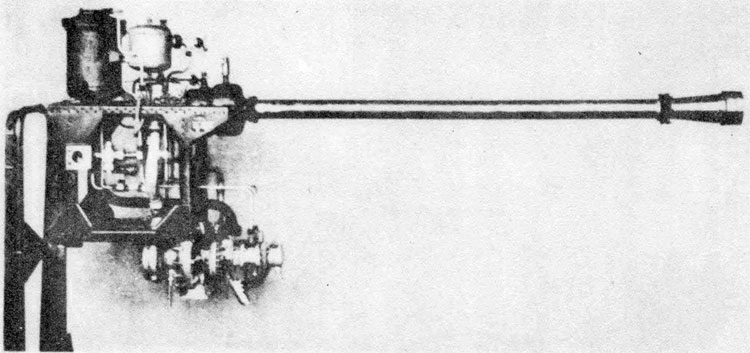

Figure 10 shows a cross section through a take-off auxiliary. Here the system has taken shape as a unit of Air Force equipment of light-weight construction but provided with all safety features. The spherical form was chosen for the pressure tank as being the lightest. The unit is built both for use with combustion of hydrocarbons and for use with T-substance decomposition alone.

At 1500 kilograms thrust lasting 30 seconds, the total impulse amounts to 45,000 kilogram seconds. The corresponding empty weight of the device is 250 kilograms, that is, 5,6 grams per kilogram second, [NACA comment; Values corrected from the German.] This weight added to the specific propellant consumption of 5,7 grams per kilogram second gives a total weight cost of 11.3 grams per kilogram second, [Values corrected from the German.]

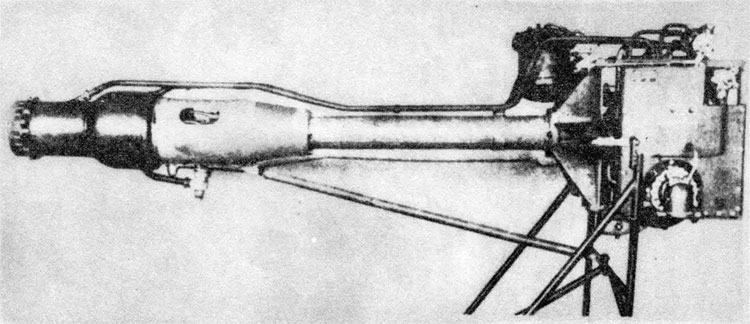

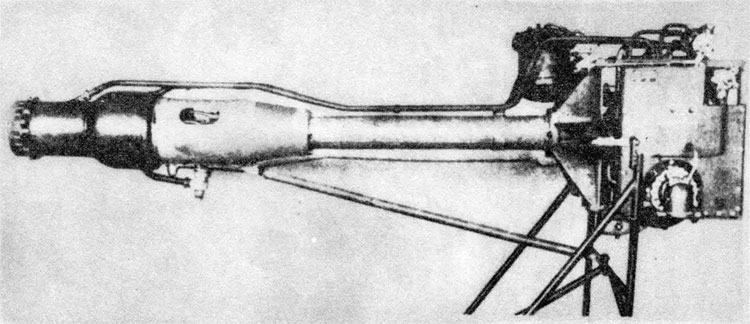

A jet torpedo (LT 1500) also using the T-substance, Z-substance fuel system is shown in figure 11. With a thrust of 800 kilograms during 106 seconds, the total impulse amounts to 84,800 kilograms. The empty weight without explosive charge is 818 kilograms, or 9.65 grams per kilogram second, With the specific propellant consumption of 5.5 grams per kilogram second, this empty weight makes a total weight cost of 15.15 grams per kilogram second. [Values corrected from the German. ] This relatively great weight is due to the heavy construction of the casing, which must withstand the stress of being dropped,

Figure 12 shows a catapult drive, which, of course, does not constitute a jet power plant in the strictest sense; however, this drive is a characteristic example of a stationary steam-jet generating device with a short operating period. An additional problem arising in this case is the generation of a quantity of steam that increases as the square of time during the prescribed operating period, a problem solved by the successive activation of different atomizer nozzles. An electromagnetically tripped valve admits air to a servomechanism throwing a high-pressure air valve that allows the air to pass by way of a surge tank to the propellant tank. From this first tank feed lines of varying length lead to the atomizer elements so the liquid arrives at the various atomizers at different times. Furthermore, a quantity of propellant is forced through a third ascending pipe into another, initially empty tank:, from which the filling of the tank must first expell the force-feed air, whereupon a pressure-feeding action gradually begins through feed lines also of different length. A plentiful supply of Z-substance is pressure- fed simultaneously with the T-substance. In this case, the citing of specific consumption, figures is meaningless. The steam generation takes place directly in the constantly increasing cylinder, space. In this unit about 65 kilograms of T-substance are decomposed in 0.5 second.

3, Beyond a certain operating period it is impossible to use pressure-feed tanks and pump feed must be adopted. Thus the pump feed becomes the most characteristic feature of the continuously operating rocket power plant.

The R-fighter, for which a thrust output that lasted several minutes and was controllable between the limits of 150 and 1500 kilograms was required, may be cited as the most typical example of a continuously operating power plant. This fighter wa3 built in an experimental version using the T-substance, Z-substance system (with a specific consumption of 9,5 g/kg sec), and in the final form using the T-substance, C-substance system (that is, T-substance with hydrazine hydrate and methanol combustion, with a specific consumption of 5,5 g/kg sec).

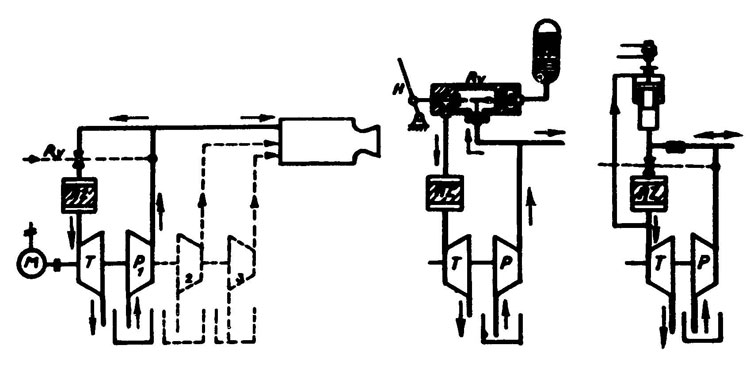

Other than the design of the jet nozzle proper and the decomposition-combustion chamber for the whole range of thrust values, the chief problem was presented by the feed-pump drive and the regulation of the feed quantity. The pumping of the propellant is best accomplished by high-speed centrifugal pumps driven by turbines running on steam from T-substance, which have been developed or are being developed for this special purpose. Fundamentally, the regulation of feed quantity can be accomplished either by regulation of the pump speed and therefore of the feed pressure or by throttling a constant pump pressure down to a combustion-chamber operating pressure. In both cases, driving the pump by means of the T-substance auxiliary drive provides a simple solution to the problem. The essential features of this auxiliary drive are shown in figure 13.

A turbine T, which is brought up to a certain speed by some means, for example by a starting motor, drives a T-substance pump. From the pressure line a secondary flow is tapped off and led through a regulator valve into the auxiliary decomposer — a surface decomposer is most suitable — in which, by use of a given concentration (80 percent), there can be generated only steam, of an exactly

determined temperature (475° C), [MCA comment: Values corrected from the German. See pt 3.] that drives the turbine. The characteristics of the pump and the- turbine are so chosen that the pump pressure is always higher than the turbine operating pressure by an approximately constant amount and therefore it is possible to secure a feed of T-substance to the auxiliary decomposer throughout the entire operating range. Each throttling value of the regulator valve is thus associated with a certain operating condition. The regulator valve may be controlled either by hand, by a tachometric regulator, or by the pump pressure. In order to bring the installation to a stop, the regulator valve or a separate cut-off valve is closed,

In the second part of figure 13, an auxiliary drive with a hand regulating device is shown. For starting, T-substance is drawn from the starting flaak A, which is under pressure by a separate small starting air flask that is not shown, by the movement of the lever E, which operates through the left-hand valve cone and the thrust rod to open the right-hand check cone and thereby permit a flow from A to the auxiliary decomposer HZ. The turbopump starts and under the feed pressure T-substance now flows to the regulator by way of the center check valve and the thrust rod rises and terminates the transmission of force from the left- to the right-hand cone, whereupon the right-hand cone begins to operate as an ordinary check valve. The T-substance from the pressure line now flows on the one hand to the auxiliary decomposer, on the other to the starting flask, which is thus filled to the highest pump pressure reached during the period of operation. Therefore, the installation is always ready to start again after being stopped. The operation of the lever may, of course, also occur indirectly, for instance by compressed air, oil under pressure, or the like.

If no strong source of flow is available for starting the installation, the third flow plan in figure 13 may also be used; in this scheme the starting propellant is pressure-fed using the differential piston principle with the initial impulse given by solenoid, gunpowder gas, or springs.

The great advantage of this auxiliary drive is that only one propellant substance and therefore only one regulating device is required for the operation of the auxiliary circuit, while the operating temperature remains absolutely constant and the steam is entirely clean and harmless. The starting process is extremely simple and can operate without any additional operating means.

Additional pumps may be added to the turbopump system; whereby, assuming uniform pumping characteristics, a propellant system using several substances could be operated without any additional regulating devices between pumps and combustion chamber.

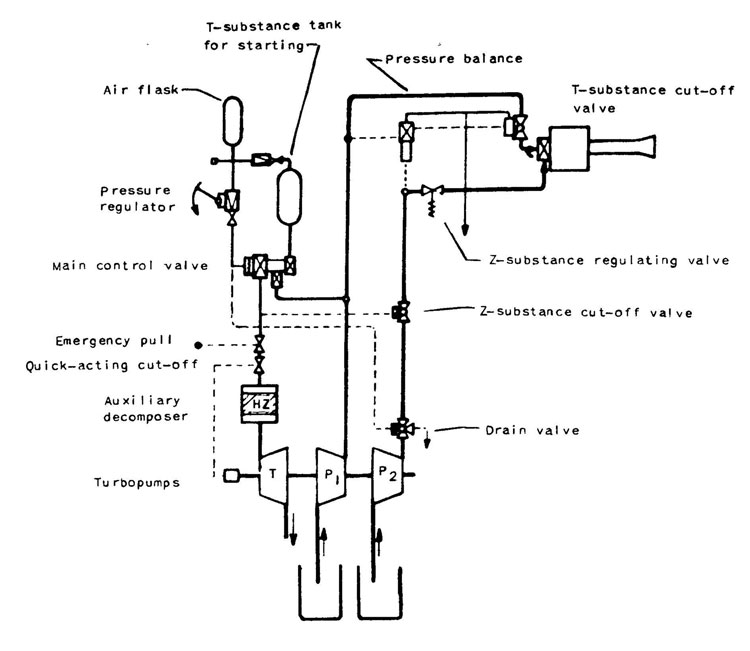

The next illustration (fig. 14) shows a diagram of the first R-fighter power plant using simple T-substance, Z-substance decomposition, The auxiliary circuit is laid out according to the diagram shown in figure 13 using a starting tank (without electric fittings). The two main feed lines are provided with cut-off valves each of which is so controlled by the pressure in the other line that if one component fails the other will be automatically cut off. The next illustration (fig. 15) is a photograph of this power plant. A remarkable point about the power plant is the design of the decomposer, which in order to shift the center of gravity forward was constructed as a very small decomposing chamber with an extremely long nozzle. The decomposition is only initiated in the chamber and is completed during the flow of the material through the long nozzle. The decrease in efficiency involved is unimportant but the shifting of the center of gravity is highly advantageous. As a prototype power plant, this unit constitutes an ideal research unit because of its highly reliable operation, small danger of fire, and the other advantages of this system already enumerated. Performance of the first very high-speed flights and very rapid climb flights as well as an extensive experimental and training program have been possible with this unit. With a total weight (exclusive of propellant tank) of only 75 kilograms, a thrust power of 3000 horsepower can be maintained at maximum speed (750 kg at 300 m/sec). This corresponds to a specific weight of only 25 grams per effective horsepower. The high specific consumption, 10 grams per kilogram second, naturally prohibits use at the front; for such use, only the hot power plant can be considered, of which an example is shown in figure 16.

In the lower part will be recognized the turbine assembly Including the two propellant pumps arranged in an auxiliary circuit flow plan such as lias just been discussed. This assembly is started by means of an electric starting motor acting through a free-wheeling clutch or a gearing to which the tachometer and air compressor may also be attached.

When a certain pressure is attained in the C-substance feed line this pressure opens two cut-off valves in the main feed lines for C-substance and T-substance and also closes drain valves in the combustion-chamber cooling jacket. These valves are necessary to prevent continued combustion in the chamber of the fuel that will drip out of the feed lines after the unit is shut off; the resulting

flames would possess 110 energy of their own and "because of the air currents around the tail in the absence of jet thrust they might come in contact with the fuselage or control surfaces. After the opening of the cut-off valves, C-substance first flows into the cooling jacket of the combustion chamber and from there to the distributing unit, which has three or more stages and is operated by the main control lever. Meanwhile T-substance flows through the pressure balance. The opening of each successive C-substance nozzle group operates through the pressure balance to effect the opening of a corresponding T-substance nozzle group.

The combustion chamber is designed as a spherical space with a Laval nozzle of fixed cross section because the obstacle presented by the cooling system makes it mechanically impossible to construct a variable nozzle. Naturally, the nozzle opening ratio cannot be so chosen as to fit all operating conditions equally well, especially those of climbing flight. The nozzle is therefore designed for operation with full thrust at sea level and also for operation in high-speed flight at high altitude, because these two operating conditions are decisive for the over-all consumption. The cooling of the combustion chamber is accomplished by C-substance, the temperature of which is raised about 100 C when operating at full thrust. Cooling by means of T-substance is also possible but requires a reliable draining action after the power plant is shut off.

The atomization of both propellants occurs in three concentrically arranged groups each having three pairs of radial-slot nozzles especially developed for this purpose. Good combustion is further promoted by the use of the antechamber process, which consists in burning about one-tenth of the total quantity of propellant as a pilot flame in an antechamber that then atomizes and positively ignites the main quantity of propellant, which is sprayed in through relatively coarse nozzle holes.

With the exception of the main propellant tanks, which are carried in the forward part of the fuselage and in the wings, the power plant is built as a unit and given three-point suspension, as shown in figure 17.

With regard to the T-substance tank, it remains to be noted that this tank may a],so be made bullet proof in exactly the same manner as bullet-proof gas tanks in which the walls are formed by several layers, some of the material being capable of swelling; but this bullet proofing will introduce a corresponding increase of weight.

The forces to which the power plant is subjected have been experimentally observed, The weight of the power plant is 165 kilograms* At a thrust of 1500 kilograms at 300 meters per second, an output of 6000 horsepower would be delivered, From these weights may be computed a specific weight of only 27.5 grams per effective horsepower.

When this power plant has been completely tested, its field of application will probably not remain limited to fighter planes and today new possibilities for its use are already appearing,

4, So far only the pure propulsion jet has been discussed in this report; it is now desirable to say a few words concerning the mixture-jet and the combined-jet power plants.

The mixture of air with the propulsive jet for the purpose of increasing the thrust — the Melot principle — is well known and has often been experimented with, Tests that gave a thrust increase of 150 percent in the test rig have also been made. However, because these values could be attained only by using bulky though lightweight auxiliary apparatus, the use of such mixing nozzles has so far never been proven to be worth while.

The mixture jet appears to be more important and valuable in the field of jet suction and compression, for example as applied to influencing boundary layers, or in ram-jet units for compressing the air in starting and for extra compression during operation to increase the power output. Investigations of the possibilities of mixture-jet use in this field are in progress now and have already yielded useful results. The mixture jet could also be used for the operation of temporary wind tunnels, which might be constructed very hastily and simply for special purposes.

The T-substance, C-substance jet and the auxiliary drive previously described are also used for these power plants because of the simplicity and reliable operation. A system very well adapted for systematic investigations, especially when particular jet temperatures are required, consists of the so-called "system 3" in which T-substance and hydrazine hydrate are used in water solutions of equal percentage strength, for example 80-percent T- substance plus 80-percent B-substance [B-substance is hydrazine hydrate. An incidental result of using this system is that for the stoichiometric ratio there results approximate equality of volume and a constant weight ratio of about 0.73. This system makes it possible, using the same test unit without interchanging any nozzles and using equal pressures, to obtain with absolute reliability specified temperatures, which are determined "by the choice of concentration. In this connection, ignition may "be obtained with solutions as weak as 45 percent.

In the survey presented, the multiplicity of possibilities for the use of T-substance in the field of reaction drives has been pointed out. Although in the field of short-period drives, T-substance must contend with the strong competition of powder propulsion and other oxygen carriers and in some cases is clearly inferior, for experimental drives and in the field of controllable power plants T-substance proves to be the best because of the favorable specific qualities as a propellant and the simplicity and reliability of power plants using it.

To the tireless energy of all coworkers, to the leadership and support of official quarters, to the willing assistance from research organizations, and not least to the cooperation of the test pilots, we owe the fact that today power plants are available that may confidently be predicted to prove themselves in attack upon all fronts even more fully than they have already done in a number of cases.

Figure I. - Energy content of T-substance solutions of 0 to 100 percent at I atmosphere absolute; t0 = 0° C.

Figure 2. - t-i diagram for T-substance.

Figure 3. - Adiabatic drop (16:1 atm abs,) and combustion temperatures as functions of concentration, mixture ratio, and excess oxygen factor. [NACA comment: T-substance, hydrogen peroxide; B-substance, hydrazine hydrate; M-substance, methanol; C-substance, hydrazine hydrate-methanol mixture; Sv-substance, nitric acid.]

Figure 4. – Freezing point of T-substance solution.

Figure 5. - Curve of detonation limits for mixture of T-substance and alcohol.

Figure 6. - Short-period power plant (expendable item), 10 to 60,000 kilograms.

Figure 7. - Flow plan of gliding bomb drive, T-Z- substance.

Figure 8. - Short-period power plant for repeated use, 0 to 2000 kilograms.

Figure 9. — Generation of high-pressure gas from T-substance. Short—period power plant for repeated use, number F 29 1009, 0 to 2000 kilograms.

Figure 10. - Take-o f f auxiliary. Figure 11. - underwater power plant LT 1500, T-B-Z-substance, 800 kilograms, 60 seconds.

Figure 12. - Flow plan.

Figure 13. - Controllable continuously operating power plant (Walter auxiliary drive).

Figure 14. - Controllable continuously operating power plant R II 203 b 0 to 750 kilograms.

Figure 15. - Controllable power plant R || 203 b T-Z-substance; 0 to 7 50 kilograms.

Figure 16. - Control table continuously operating power plant R II 211 0 to 15 00 kilograms.

Figure 17. — Controllable continuously operating power plant R || 211 T-C-substance; 0 to 1500 kilograms.

Translation:"Bericht uber die R-Triebwerke auf Grundlage des T-Stoffes." R-Antriebe, Schriften der Deutsche Akademie der Luftfahrtforschung

Heft 1071, Nr. 82, 1943

Translated by Edward S. Shafer, 1947.